Connected Equipment and Artificial Intelligence in Industrial Operations

Implementing a solution to manage and maintain globally distributed industrial equipment —such as that used in the food processing industry— presents significant logistical challenges. When this equipment is further enhanced with embedded digital capabilities, the complexity of comprehensive equipment management and its digital features increases substantially.

This was precisely the situation faced by our client, a manufacturer of real-time food sorting equipment for the food processing industry. They required a solution that combined connectivity with lifecycle management for their equipment —covering both hardware and the classification models based on artificial intelligence applied to real-time imaging, as well as the embedded software controlling machine operation.

These machines operate 24/7 at high speed, processing products such as fruits, pickles, and meats, whose characteristics vary depending on the season and batch. Therefore, fine-tuning the parameters for detecting and classifying product quality requires multiple sensors, multispectral imaging, high-speed sorting systems, and machine learning techniques.

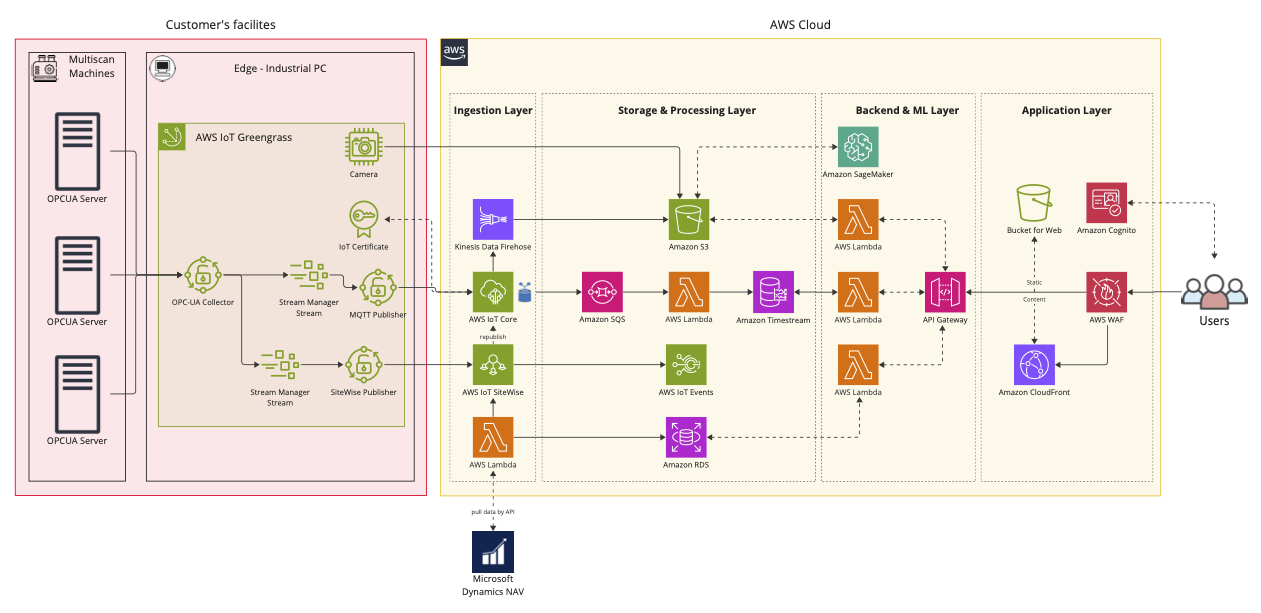

In collaboration with GALEO, an architecture was developed that combines Edge technology with AWS cloud services, providing a scalable and flexible solution that enables:

- Remote monitoring and predictive maintenance: Real-time monitoring allows faults to be detected even before the customer notices them, minimizing downtime.

- IoT data–driven diagnostics: Sensors installed in the machines continuously collect telemetry, which is sent to the cloud in real time. This continuous data flow is essential for diagnosing issues on a global scale.

- Calibration and quality control: The architecture allows remote sensor adjustments and calibration improvements based on image analysis. By integrating advanced data analytics techniques, the system ensures that the final product quality remains consistently optimal.

- AI model lifecycle, automated classification, and continuous learning: Through defined MLOps pipelines, machines autonomously execute classification models, detect product defects, and improve accuracy through customized retraining for each client’s specific context.

The developed technological capabilities have enabled the equipment manufacturer to offer:

- Centralized asset management: An inventory and asset management system simplifies the registration and deployment of new equipment across multiple locations, streamlining implementation for customers.

- Personalized performance insights: The solution provides a comprehensive view of machine status and performance, with real-time alerts that facilitate proactive maintenance.

- Role-based access model: Both customers and maintenance staff can access the centralized platform under a secure, role-based access framework, ensuring safe and efficient asset management.

- Value-added services for clients: Through a SaaS platform, the manufacturer can now offer services that optimize the equipment lifecycle and ensure each machine is specifically tailored to the client’s operational context.

Thanks to this solution, the client now efficiently manages the first 500 units deployed worldwide, optimizing performance and learning throughout their lifecycle while minimizing on-site maintenance interventions.

This system has become a key tool for reducing operational effort, improving response times, and ultimately enhancing quality and productivity in industrial food processing operations